Multiaxis and precision machining

Multiaxis 5-axis machining enables to machine the five faces of a workpiece in one shot for speed and precision.

Our know-how focuses on this kind of machining and for different materials with the following techniques: milling, turning, EDM cutting and grinding.

The realization of all our precision mechanical parts is done in our 3 workshops in Faverois, France.

We are also able of large series production.

Machined materials

Specialized in machining since 1993, USIDUC® knows how to machine all the following materials:

Plastics

Polyamides PA6, PA66

Polyacetal

High Density Polyethylene PEHD

Polycarbonate

PVC

PTFE, PEEK

Polypropylène

ABS

PAI, PES, PEI, PSU, PVDF, TORLON, PPS RYTON R4

Composites

FR4

G11

PI29

Bakelite Canvas

Bakelite Paper

Mat Epoxy

Mat Polyester

Polyamide

Silicone

Mica

Phenolic

Cement

Ceramics

Alumina

Zirconia

Silicon carbide

Silicon Nitride

Zirconium

Metals

Hastelloy

Inconel

Waspaloy

Rene alloys (41, 80, 95, 108)

Haynes alloys

Incoloy

MP98T

TMS alloys

Stellite

Carboloy

CMX

Inconel 718

HR 120

GDT 140

Stainless steels

Titanium

Alluminium

Copper

Bronze

Brass

Retro-engineering

Retro-engineering, or reverse engineering, consists of creating a 3D file from an existing part. This retro-engineering process, also known as retro-design, is done by scanning the object at 360 ° so that it can be represented in 3D. It is thus possible to make replicas of the piece. Reverse engineering is useful when you do not have 3D files that can be used in CAD (Computer Aided Design).

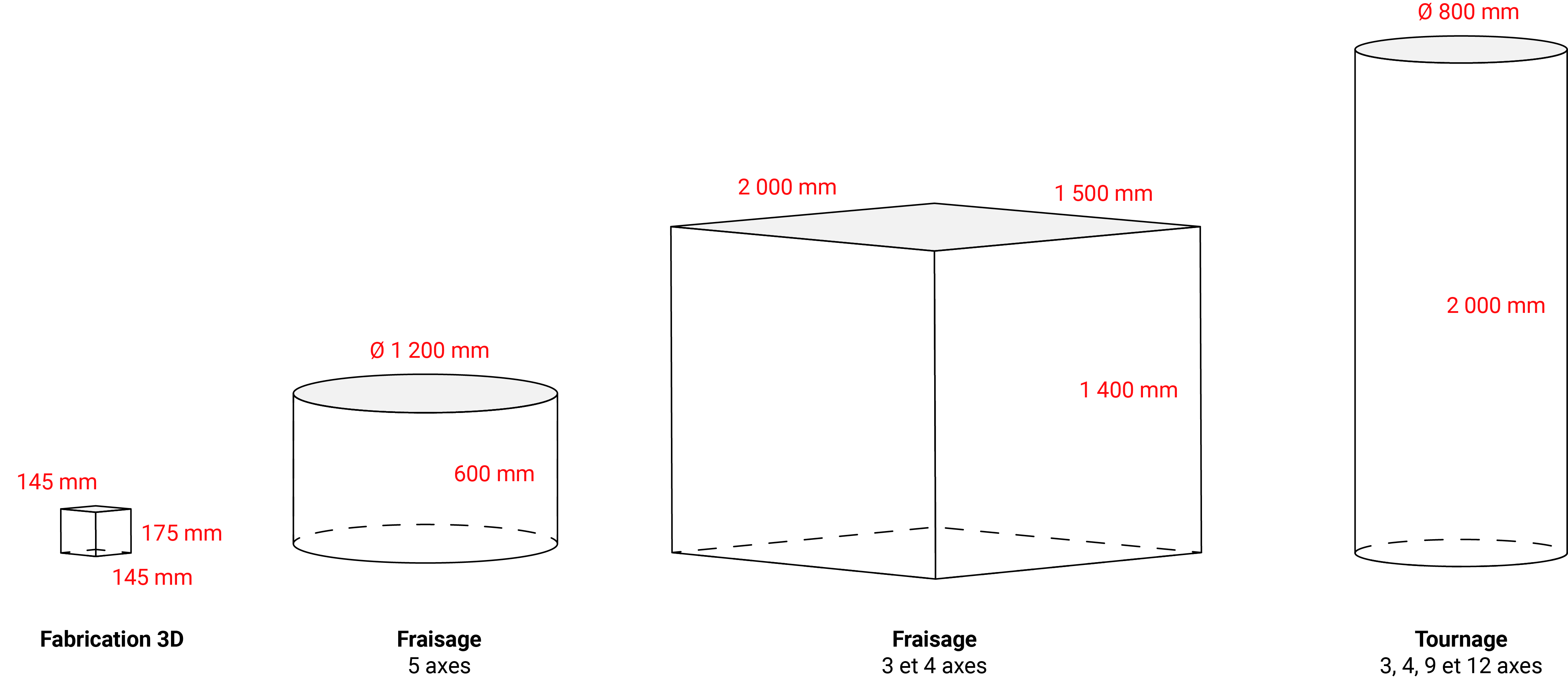

Our manufacturing processes

- Machining / milling / turning 3, 4, 5 axis robotic and palletized

- Wire Cutting / Wire EDM

- Pre-impregnated insulation tube

- Additive manufacturing

- 3D scanning and scanning: Zeiss three-dimensional controller

- Computer Aided Design: Solidworks Software

- Computer Aided Manufacturing: Gibbscam / Missler Software

Our machinery

- A fleet of 30 production facilities, including 20 CNC machining centers

- 3 and 4 axis turning centers

- 3, 4 and 5 axis milling centers

- 4 wire spark erosion centers

- 15 skilled operators / technicians

OKK VCX350, OKK VCX500, OKK VP600, OKK VG5000, OKK HM1250S, OKK HMX6000, OKK HMX8000, HYUNDAI WIA LV800RM, ZEISS CONTURA, ZEISS DURAMAX, FORMLABS, FANUC ROBODRILL, RENISHAW OMP 40, RENISHAW OMP 50, BLUM, ROBOJOB MILL ASSIST, LANG TECHNIK ROBOTREX, QUASER MV214P12, QUASER MV234P12, OPTIFIVE.

Capability according to processes

Our automated controls

To guarantee the quality of our work, we have implemented Renishaw and Blum automated control systems in our 5-axis machining centers.

How is a quality control performed? The control is performed by a software-based system and a machine-mounted part probe. The part is thus checked before dismantling and within our machining center.

In addition to saving time, this process allows 100% control of production and cutting tool changes at the right time.

For even greater precision, we are also equipped with an Optifive pivot point calculation system.

Our quality certifications

USIDUC® has a fleet of machines able to meet all your needs in manufacturing and machining parts. We are ISO 9001 and EN 9100 certified.

Develop your projects quickly with the Starter Pack

A true accelerator for the development of your projects, the Starter Pack allows you to quickly move from the idea to the prototype, from the prototype to the pre-series and from the pre-series to the series.

The project leader is accompanied throughout these stages by an Innovation Officer who will have resources such as an additive manufacturing center, scanning tools and access to the UTBM CrunchLab which includes laser cutting and other manufacturing and scanning processes to carry out his project.