Pre-impregnated tubes

USIDUC® is one of the last company to produce pre-impregnated insulation tubes in France. This technique consists in creating very strong, waterproof and insulating parts from strips of glass fabric pre-impregnated with epoxide resin. It requires a real know-how that we have perfected over the last 20 years.

How are the tubes made of prepreg?

Our tubes are made according to a unique know-how from large rolls of glass fabric pre-impregnated with resin. These rollers have a width of 1100 mm which defines the maximum length of our tubes.

Step 1: the winding

The tubes are made by wrapping around a mandrel the fabric previously heated to high temperature. This winding step is a key step in the manufacturing process: the speed at which the fabric must be wound depends on the characteristics of the tube and determines the success of the manufacturing process.

We use two types of fabrics of different thicknesses (0.11 mm and 0.22 mm) chosen according to their level of fire resistance and the dimensions of the finished product: the number of superimposed layers of fabric defines the final thickness of the tube. The diameter of the mandrel, ranging from 5.1 mm to more than 500 mm, gives the inner diameter of the tube.

Step 2: annealing

Before being placed in an oven, the roll of fabric is covered with a heat-shrinkable tape that prevents the fiberglass from unwinding. This stage lasts approximately 3 hours, whatever the diameter of the tube.

Step 3: Finishing

When the tube is cooked and cooled, the mandrel is removed. The tube is then sawn to obtain the desired length, rectified to reach the correct diameter and machined if necessary.

All tubes are machined to comply with the dimensions of the drawings provided by our customers, with a tolerance around 0.05 mm. Depending on the specifications given with the order, the tube can be polished to obtain a greater or lesser roughness, varnished to enhance their resistance to moisture, marked with ink, drilled or machined.

Before shipping, we always carry out a careful verification of the quality of our tubes: dimensions, surface condition, sealing and electrical insulation.

What are the prepreg tubes used for?

Our tubes are used in a wide variety of industries: medical, transportation, oil, industry, etc.

Our tubes are for example used in aluminum smelters, glassworks or TGV engines to withstand temperatures up to 250 ° C.

They are also used for their electrically insulating properties in aeronautics and aerospace to protect the power boxes in planes and satellites.

Finally, our tubes are used to ensure the tightness of certain parts, such as torpedo and missile power boxes.

Pre-impregnated tubes, but not only!

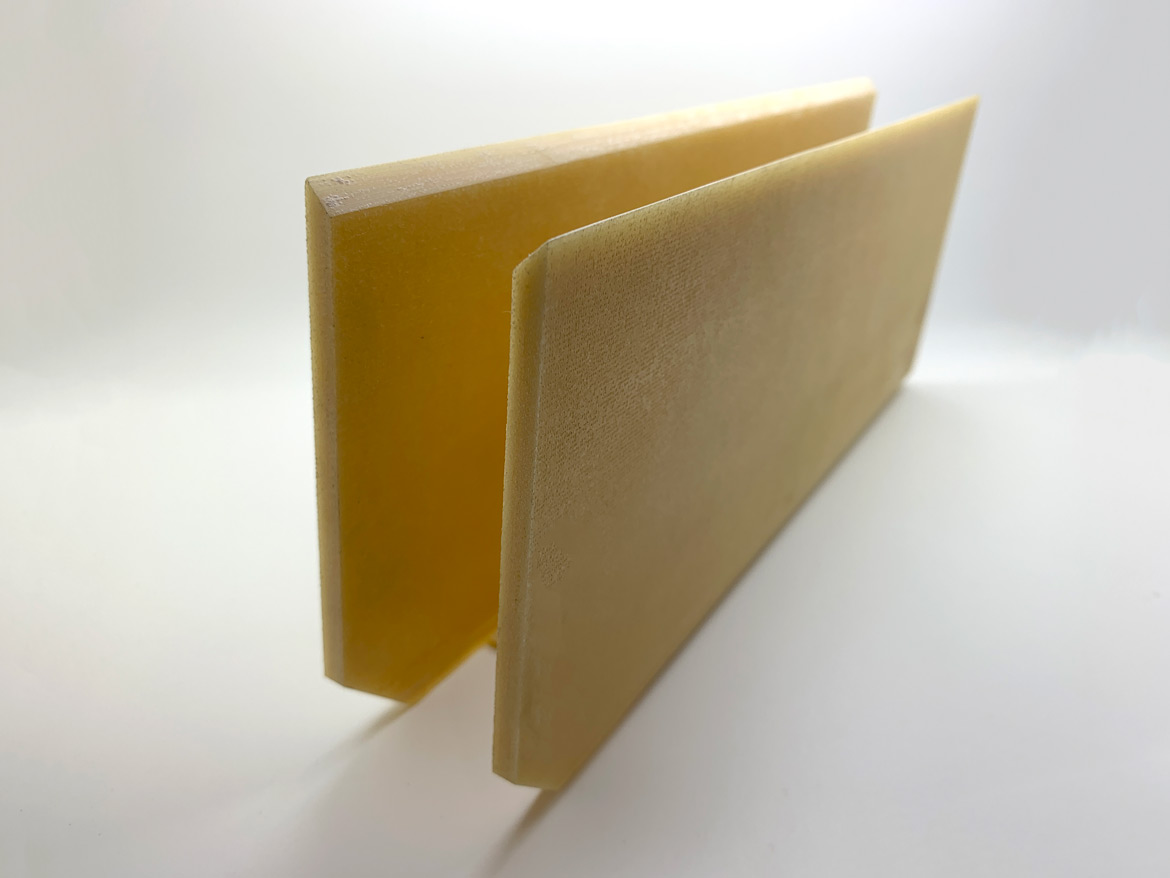

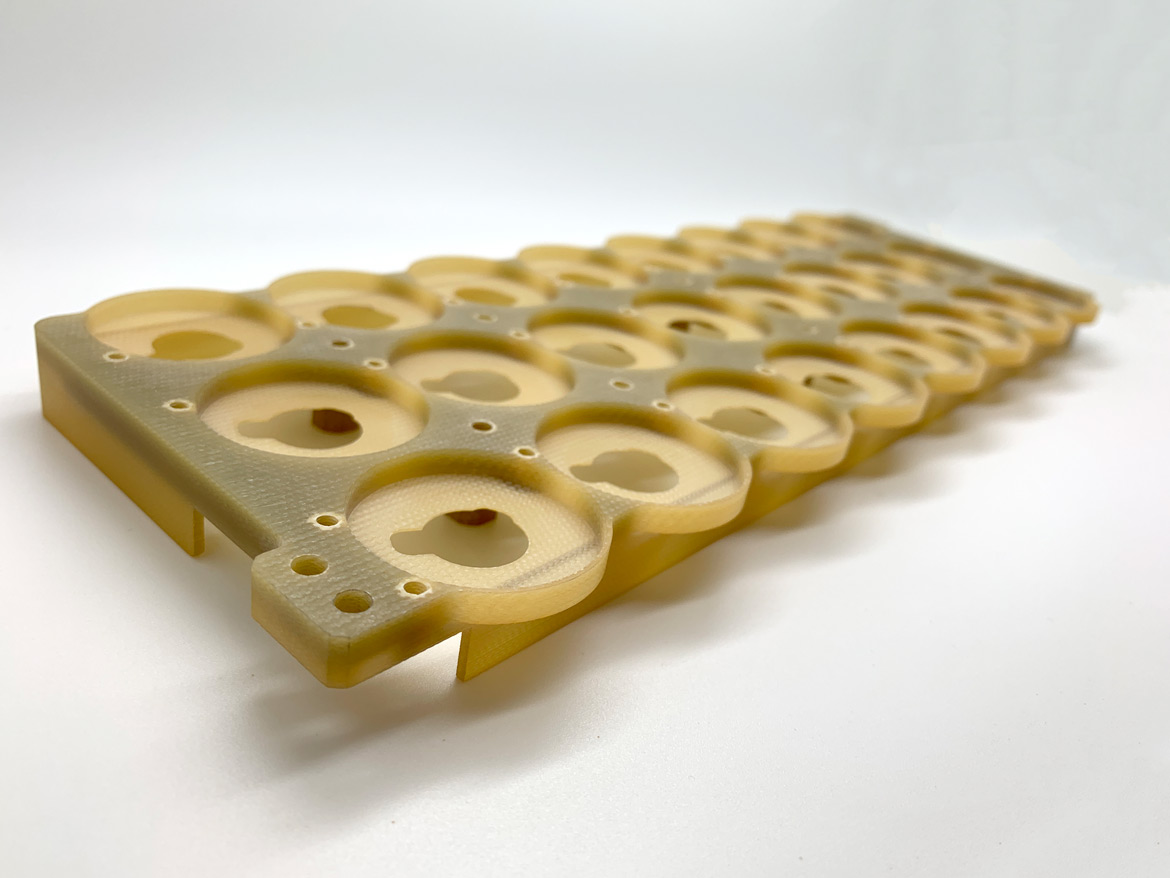

We also use prepregs to make solid or perforated plates that have the same properties as the tubes.

Pieces of pre-impregnated fabric are cut and superimposed in a mold until the desired thickness is achieved. The manufacturing process and available finishes remain the same as for the tubes.

USIDUC® also manufactures electrical insulation systems for metal parts that are pressfitted around composite cores to ensure a tight and long-lasting assembly.